Modified: Dec. 5, 2014

LW900A / LW900-2AR - Ø105 ~ 160

LW500A / LW550-2AR - Ø90 ~ 100

The Bale Wrapper that Livemac has developed for the first in Korea in 2003 stems from our cuttingedge technology, which has been created from our repeated research and development efforts.

The core advantages of Bale Wrapper lie in an easy operation at anytme and anyplace with a wireless remote controller. This wireless remote controller with the high tech functions ensures an operation even 100 meters away, which now makes it possible to have prompt and convenient work regardless of job conditions. There is no need for any wiring job on the modules to operate the wireless remote controller. Livecmac's Bale Wrapper, upgraded one step further by taking the wireless remote controller, leads to your success in all wrapping works.

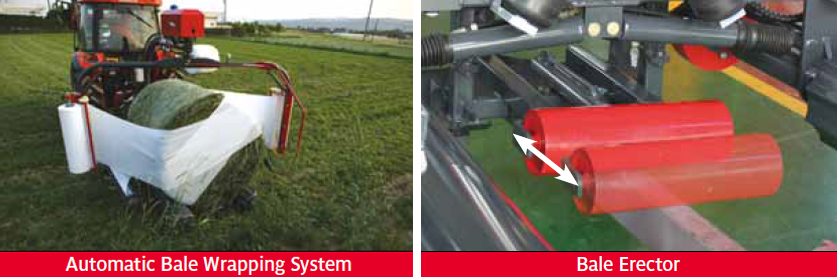

Wrapper can be drive in a high speed as it can move while you are wrapper solidly to load bales away from the bottom by applying 3-point hitch to attaching to your tractor. You can also carry out your works faster as you can move while wrapping if necessary. The arm-type wrapper carries out loading and unloading at the same time with two arms while two arms while loading and unloading bales, in order to realize a faster working speed.

Twin-arm Wrapper realizes the best conditions for fermentation as it encloses the bales surely drains air in a fastest time.

Any damage to the machine as well as any accident to people can be safely prevented as its rotation is automatically stopped when any objects touches the safety bar in the rotating arms during wrapping operation.

Our hydraulic power controller moves slowly when the wrapping operation starts, and realizes an excellent performance in a high speed. It performs uniform and solid wrapping operation by minimizing all loads with slow operation to the final. The smooth operation can be continuously maintained without stopping the arms even though a different hydraulic power is suddenly applied during the wrapping operation. The hydraulic power control system prevents the wraps from tearing or defects caused from dislocations, which stands forLivemac's differential technology for producing the best quality of silage. In addition, the gear transmission device attached to the wrap-loosening equipment helps to ferment the silage by adjusting the looseness of wraps to a desired strength according to the weather conditions.

Wrap width can be easily changed according to the usage of wraps.

The sliding-cut pipes are adopted for slow cutting so as to prevent wraps from tearing. More advantages of our Wrapper are to recover the shape of any improper or dented bales.

Functions such as controlling the number or wrapping can be arbitrarily adjusted with a simple controlling in your tractor and operations can be done with onetouch function either in the semi-automatic mode or automatic mode.

out loading, wrapping and unloading jobs individually by stage. While working in the automatic mode, by pressing the automatic mode, you may increase the efficiency of your work by carrying out loading, wrapping and unloading of the bales automatically and sequentially.

| MODEL | LW900-2AR | LW900A | LW500A | LW550-2AR |

|---|---|---|---|---|

| DIMENSION (cm) | 327×201×232 | 258×160×270 | 210×140×210 | 293×256×212 |

| WEIGHT (kg) | 965 | 857 | 652 | 720 |

| BALE DIAMETER (cm) | Ø105~130(*160) | Ø105~130(*160) | Ø90~100 | Ø90~100 |

| BALE WEIGHT, MAX (kg) | 800 | 800 | 400 | 400 |

* Bale Diameter of Max. 160cm: Available on the request of Distributor

Field operation in Nov. 2014 (Straw)

LW900-2AR @ Elmore, Australia in Oct., 2014 (Hay)

4 kinds of Bale Wrappers Available!

LW900-2AR / LW900A (Φ105 ~ 160)

LW550-2AR / LW500A (Φ90 x 100)

Click to subscribe to RSS for real time updates

http://en.livemac.co.kr/product/latest/feeds/

You could add above URL in your favorite RSS reader