Modified: Dec. 5, 2014

L325 (Ø125x120)

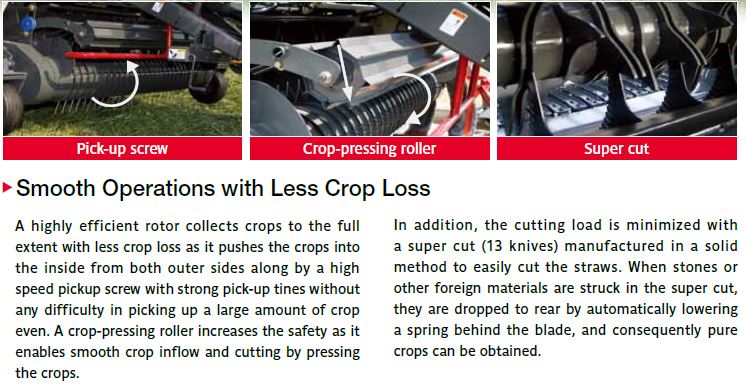

A highly efficient rotor collects crops to the full extent with less crop loss as it pushes the crops into the inside from both outer sides along by a high speed pickup screw with strong pick-up tines without any difficulty in picking up a large amount of crop even. A crop-pressing roller increases the safety as it enables smooth crop inflow and cutting by pressing the crops.

In addition, the cutting load is minimized with a super cut manufactured in a solid method to easily cut the straws. When stones or other foreign materials are struck in the super cut, they are dropped to rear by automatically lowering a spring behind the blade, and consequently pure crops can be obtained.

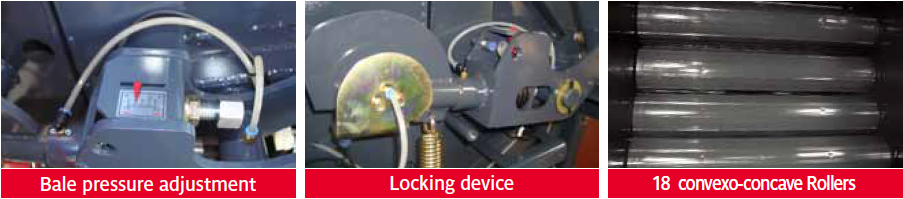

The well-compressed bales become a high quality of feed from the good fermentation because they contain less air due to our advanced bale compressing technology.

Our roller-type round baler engineered with our accumulated design know-how forms higher compressed bales for hay and straw by the precise and solid grabbing device responding to the inflow volume by the pressure leading time adjustment as soon as bale is formed. However, it is useless to have any high hydraulic power if the grabbing strength of the rear door is not enough. To prevent this phenomenon, our hooktype locking device at the rear door solidly grabs the bale with no shake under the high pressure, and forms bales in a high compression.

The hitch-type connection to the tractor makes it possible to have speedy attachment and detachment and easy to turn left or right during movement.The auxiliary wheels maintaining a constant height from the ground to the pickup device while in operation can be either attached or detached, which makes it possible always to have an easy movement as they can be stored on a shelf of the baler when you pass through any narrow road.

Automatic Oiling Device increases durability and anti-wearing by softening the gaps of the rotating or contacting points of the operating parts and reducing the power consumption.

The gearbox ensures fast and stable operation with less power not giving much burden to the machine when any heavy load is imposed, because it evenly distributes the initial in-taking power necessary for driving the parts of the baler to the left and the right.

Livemac's unique design technology ensures fast and solid baling with tense and uniform netting.

| MODEL | L325 | L325C |

|---|---|---|

| BALE DIMENSIONS (cm) | Ø125x120 | Ø125x120 |

| PTO SPEED (rpm/min.) | 540 | 540 |

| MIN. POWER REQUIREMENT AT PTO (Kw (HP)) | 52 (70) | 67 (90) |

| PICK-UP WIDTH (cm) | 200 | 200 |

| PICK-UP RAKE WIDTH (CM) | 166 | 166 |

| ROLLERS | 18 | 18 |

| TINE BARS / TINES PER ROW | 25/4 | 25/4 |

| OVERALL DIMENSIONS (cm, L-W-H) | 349 x 243 x 240 | 349 x 243 x 240 |

| WEIGHT (kg) | 2890 | 3180 |

| NET WRAPPING UNIT (ELECTRIC CLUTCH) | STD | STD |

| IN-CAB ELECTRONIC CONTROL BOX | CONTROL BOX | CONTROL BOX |

| SUPERCUT DEVICE | - | 6 KNIVES |

| FEEDER | ROTOR | ROTOR |

| AUTOMATIC CHAIN LUBRICATION | STD | STD |

| MANUAL LUBRICATION SYSTEM FOR ROLLER BEARINGS | STD | STD |

Field operation in Nov, 2014 (Straw)

Field Demonstration @ Elmore Field Days in Australia in Oct., 2014 (Hay)

Click to subscribe to RSS for real time updates

http://en.livemac.co.kr/product/latest/feeds/

You could add above URL in your favorite RSS reader